Dielectric fluid & Chemicals

Dielectric fluid & Chemicals

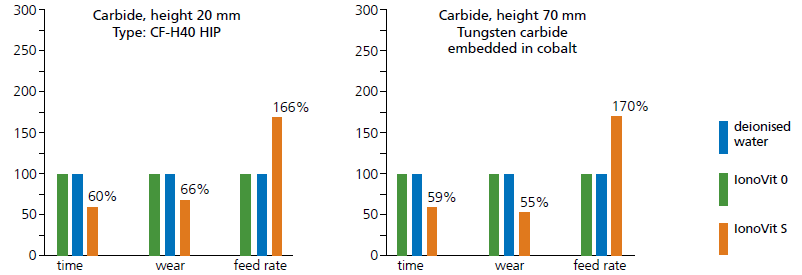

IonoVit S for fast hole drilling

IonoVit S is a high-performance dielectric designed for economic and fast working from an electrode diameter of 0,5 mm. It is also suitable for the processing of aluminum. Work pieces made of ferrous metals are temporarily protected from corrosion.

IonoVit S is a ready-to-use product. The concentration is regulated using a hand refractometer: The refractometer display for the ready-to-use IonoVit S is 7,0 % Brix.

Measuring device:

- Refractometer 7% Brix (water down only with deionised water)

Peripheral requirement:

Water treatment

- Dielectric aggregate with filter

- Integrate the cooling coil into the cooling system – recommended for reproducible quality (option) –

- Normal electrode quality is sufficient

IonoVit S – Your benefits

- Free of heavy metal and chlorine compunds

- Low electrode wear

- No foaming

- Little time exposure during drilling

- Temporary corrosion protection

- Mild in odour

IonoVit 0 for precision hole drilling

This new development by oelheld, a water-based medium which contains proper additives, guarantees the manufacturing of reproducible and high-quality holes for electrode diameters of 0,1 – 3,0 mm and larger.IonoVit 0 is delivered ready-to-use. The brix-value is in a range of 5% – 7%. A dielectric aggregate (water treatment) is necessary, which is responsible for a good quality in cooperation with the mixedresin cartridge. The medium should be cooled as otherwise a steady performance cannot be reached.

Measuring device:

- Refractometer 5% – 7% Brix (water down only with deionised water)

- Conductivity meter: conductance 0 – 10 μS/cm

- pH-value test strip 5 – 7

Peripheral requirement:Water treatment

- Dielectric aggregate with filter and deionised resin absolutely necessary

- Integrate the cooling coil into the cooling system – recommended for reproducible quality (option) –

- Good electrode quality (electrode with bar)

IonoVit 0 – Your benefits

Steel machining

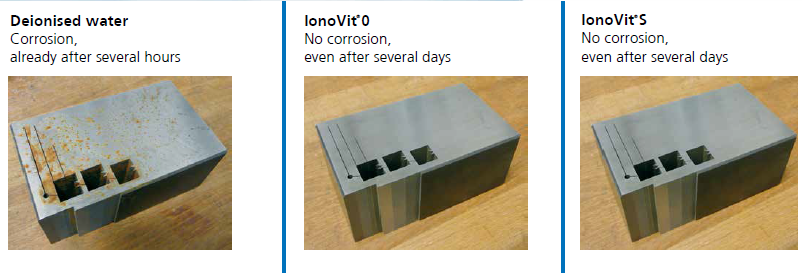

- No corrosion formation

- Free of heavy metal and chlorine compounds

Carbide machining

- No visible cobalt leaching at bore entrance

- Technological changes at the machine are not necessary

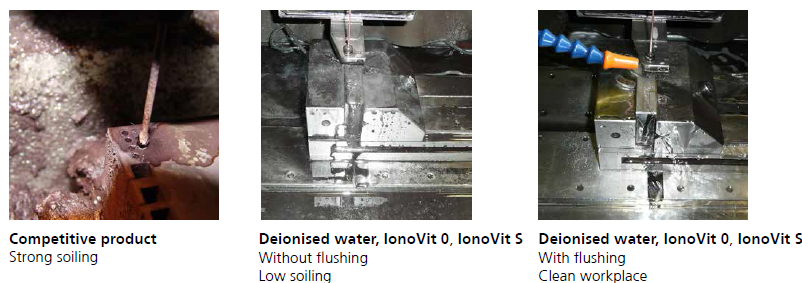

- No machine soiling

- Free of heavy metal and chlorine compounds

Distinction

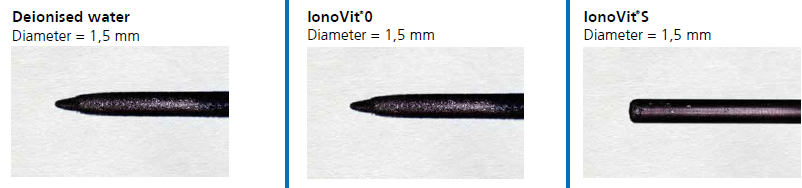

Drill holes in steel and carbide (electrodes ø 1,5mm)

Electrode wear

Corrosion

Cleanness

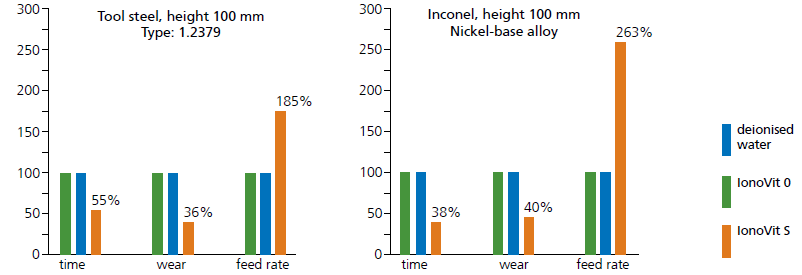

Benefits of IonoVit S against deionised water / IonoVit 0

Benefits of IonoVit S against deionised water / IonoVit 0